Welcome

to the EPE Online

Desoldering

Guide

Photo Gallery

|

|

|

|

Return

to Main Guide | Copyright

| EPE Online Home Page

Soldering Photo

Gallery

|

|

| De-soldering

is required when electronic components need to be removed from a circuit,

usually because they are faulty. It may sometimes be necessary during testing

or assembly, if a wrong part has been fitted or a modification has to be

made. In the field, it's not uncommon for faulty components to be swapped

out, or poor joints (perhaps "dry" joints) to need re-making properly,

months or years after manufacture. Experienced engineers can often diagnose

a particular faulty joint immediately, because they may have seen the same

problem on similar equipment before, especially if it has a "reputation".

A proper desoldering technique can soon be acquired with practice - all

you need to do is buy some scrap boards to have a go with, and desolder

to your heart's content!

The photo sequence

below illustrates the basic steps for desoldering a printed circuit board,

in order to remove a faulty part. Both a desoldering pump as well as desolder

braid are illustrated. Some real-life examples of poor soldering are shown

too, in my Black Museum of Bad Soldering!

Remember that

"Practice-makes-Perfect", and in the long run it costs less to get

it right than it does to get it wrong! |

|

Enjoy!

-- Alan Winstanley.

|

|

|

The

two solder joints to be desoldered, to enable a faulty component to be

removed. |

| If

using a desoldering pump, apply the iron first to melt the solder (1-2

seconds). Ensure the pump is 'primed' and ready to go... |

|

|

The

nozzle of the desoldering pump is applied to the molten solder and the

spring-loaded plunger is then released, drawing the solder up into the

pump. Repeat if needed. |

| The

first joint, now desoldered. The second joint will be desoldered using

braid... |

|

|

Select

a suitable width of braid, and press it down onto the COLD joint using

the hot tip of the iron. |

| Molten

solder is drawn up by capillary action into the braid. Care not to overheat,

or 'drag whiskers' of solder over the board, nor let the braid solidify

on the joint! |

|

|

The

component dropped out of the board after desoldering. Sometimes, it may

need persuading with pliers.... |

| Close-up

shot of both joints, now desoldered and ready for the replacement part

to be fitted. |

|

|

The Black

Museum of Bad Soldering

|

| The following

are all genuine examples of bad soldering which have not been retouched

or reworked in any way. |

|

|

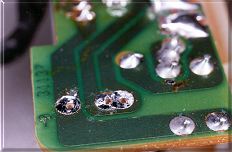

Tenfold

excess of solder, and (extreme left) incomplete joint with poor coverage.

There is no need to add more solder "for luck". |

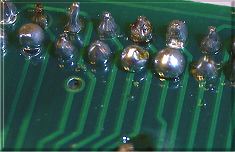

| One

example of several dry joints found within a commercial PSU adaptor for

a computer peripheral. |

|

|

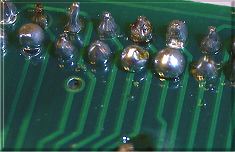

Hmmmm...

this joint looks somewhat suspect as well... |

| A

close-up reveals the terrible standard of soldering (and quality control),

with a fracture visible on this ground/ earth joint. |

|

|

How

not to make a mains voltage soldered joint. This went "dry" and starting

arcing, nearly zapping the equipment. It is also a fire hazard. |

| The

same mains connection, the wire merely being 'tacked on' with a blob of

solder. |

|

|

| All

photos are Copyright © Alan Winstanley 1997. You may download them

for personal use, or for training or educational purposes only. They may

not be used on a commercial or sponsored web site without the prior permission

of the author (conditions apply). If you wish to use these pictures for

any commercial reasons, e.g. to enhance any commercial product, enframe

in any external commercial web site or apply for any other commercial use,

you must seek the author's prior approval first (email Alan Winstanley

at alan@epemag.demon.co.uk).

Very high resolution photos with licence for reproduction are also available

on CD from the author, on payment of a royalty. Please enquire if you have

similar macro photography assignments you would like to be quoted for and

undertaken.

For any interested

photographers: the photographs were taken by the author using a Minolta

X-700 SLR with 50mm Minolta MC manual-focus macro lens at f11-16, coupled

to a Minolta Auto 80PX macro ring flash gun. Film was 3M Colour Print 200.

The prints were scanned using an HP ScanJet 6250 flatbed scanner, and enhanced

using JASC Paintshop Pro 5 with filters, before uploading. |

|