Welcome

to the EPE Online

Basic Soldering

Guide

Photo Gallery

|

|

|

|

Return

to Main Guide | Copyright | EPE

Online Home Page

Desoldering Photo

Gallery

|

|

Soldering

is a delicate manual skill which only comes with practice. Remember that

your ability to solder effectively will determine directly how well the

prototype or product functions during its

lifespan. Poor

soldering can be an expensive business - causing product failure and downtime,

engineer's maintenance time and customer dissatisfaction. At hobbyist level,

bad soldering technique can be a cause of major disappointment which damages

your confidence. It needn't be like that: soldering is really easy to learn,

and like learning to ride a bike, once mastered is never forgotten! These

ten photos illustrate the basic steps in making a perfect solder joint

on a PCB. If you're a beginner, our advice is that it's best to practice

your soldering technique using some clean, new parts with perhaps some

new stripboard (protoboard). Be sure to avoid using old, dirty parts; these

can be difficult if not impossible to solder. |

|

Enjoy!

-- Alan Winstanley.

|

|

|

Boards

must be clean to begin with, especially if they're not previously "tinned"

with solder. Clean the copper tracks using e.g. an abrasive rubber block. |

| Clean

the iron "bit" (tip) using a damp sponge. The iron featured here is an

Ungar Concept 2100 Soldering Station. |

|

|

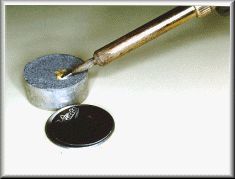

A

useful product is

Multicore's Tip Tinner Cleaner (TTC) - a 15 gramme tin

of special paste which cleans and "tins" the iron, in one go. |

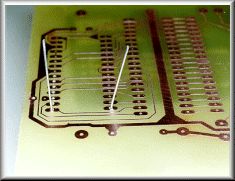

| Insert

the components and splay the leads so that the part is held in place. |

|

|

It's

usually best to snip the wires to length prior to soldering. This helps

prevent transmitting mechanical shocks to the copper foil. |

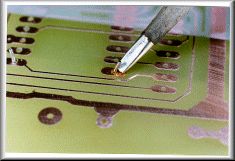

| Apply

a clean iron tip to the copper and the lead, in order to heat both items

at the same time. |

|

|

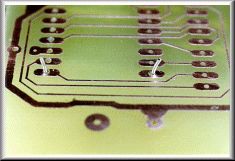

Continue

heating and apply a few millimetres of solder. Remove the iron and allow

the solder joint to cool naturally. |

| It

only takes a second or two, to make the perfect joint, which should be

nice and shiny. Check the Guide for troubleshooting help. |

|

|

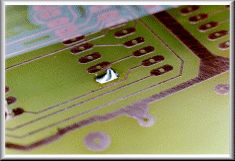

An

example of a "dry" joint - the solder failed to flow, and instead beaded

to form globules around the wire. |

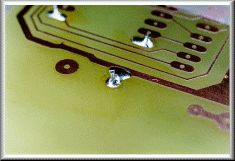

| "Solder

Wick" is a cheap and very effective way of desoldering a joint. Take care

not to overheat the board. Alternatively, use a desoldering pump. |

|

|

| All

photos are Copyright © Alan Winstanley 1997. You may download them

for personal use, or for training or educational purposes only. They may

not be used on a commercial or sponsored web site without the prior permission

of the author (conditions apply). If you wish to use these pictures for

any commercial reasons, e.g. to enhance any commercial product, enframe

in any external commercial web site or apply for any other commercial use,

you must seek the author's prior approval first (email Alan Winstanley

at alan@epemag.demon.co.uk).

Please enquire if you have similar macro photography assignments you would

like to be undertaken.

For any interested

photographers: the photographs were taken by the author using a Minolta

X-700 SLR with 50mm Minolta MC manual-focus macro lens at f11-16, coupled

to a Minolta Auto 80PX macro ring flash gun. Film was Kodak Gold 200. |

|